The Top Four Factors Facing Rugged Industrial Computers

Rugged industrial computers and rugged embedded computers are specially designed to operate reliably in harsh environmental conditions. Specifically, they are built to withstand conditions in which standard consumer model PCs would either suffer performance loss or failure.

These environmental conditions create challenges to computer reliability:

- Extreme temperatures – both hot and cold

- High levels of shock and vibration

- High levels of dust and particulates and/or the presence of moisture

- The presence or possibility of power disturbances

Many more environmental conditions affect the performance and health of computers and electronic devices, but these are among the most common. Developing and manufacturing computers and devices to meet these challenges involves an extensive process of evaluation, prototyping, and testing each component and the system against potential environmental challenges.

Extreme Temperatures

Extreme heat is one of the most damaging environmental conditions to computers. Exposure to high-heat environments will, over time, cause individual components to malfunction, fail, or even melt in extreme cases. This is compounded by the fact that even with normal operation, computers generate heat.

In standard consumer model PCs, the internal components are generally cooled by an internal fan. Fan-cooling is an acceptable solution for off-the-shelf consumer PCs, but it introduces several drawbacks for rugged industrial computers. First – and highlighted more in the below sections – one of the major engineering and design concepts for rugged devices is the elimination of moving parts. Fans, and other moving parts, introduce a point of failure and ultimately increase the cost and complexity of the system. Second, fans generally require the placement of vents or holes in the enclosure to expel hot air. These vents and holes have the negative effect of exposing the internal components to dust, particulates, and moisture which runs counter to the need for rugged devices to be dust and water-resistant.

In rugged industrial computer design, there are several key strategies and approaches to cool the internal components. The early product design phase begins in simulation. Once the device’s operating temperature range is defined, all potential internal components are run through exhaustive simulations to find those with the optimal thermal properties. Further, once final components are selected, component conduction can be optimized using fine surface finishes to encourage more efficient connections, reducing thermal energy. Simulations also help to determine a physical shape and component layout that promotes internal heat dissipation.

Once the components and the physical shape of the computer are decided, component and circuit placement are tested. For circuit placement, the goal is to reduce the proximity between heat-producing components and interspersing them with heat sinks or heat pipes to further disperse the internal heat. Finally, the exterior body assembly serves as an effective heat dispersion avenue. An enclosure with minimal locking points reduces thermal resistance, improving heat conduction and allowing the energy to efficiently escape the system. The physical shape of the enclosure can be manipulated to further disperse heat by including fins or rods depending on the final location of the computer.

Shock and Vibration Resistance

At the simplest level, a heavy vibration environment can dislodge internal components. This effect is most severe in components that feature moving parts, specifically cooling fans, HDDs, and internal cabling. Therefore, the beginning point of creating a vibration-resistant computer is to eliminate moving parts. Several of these solutions help in thermal management in support of improved shock and vibration tolerance:

- Fanless, passive cooling designs eliminate some of the moving components that are most affected by high-vibration environments.

- Incorporating Solid State Drives (SSDs) – instead of HDDs which are prone to vibration failures as they feature a spinning disk as data storage – makes the computer faster, cooler, and less susceptible to vibration damage.

- Cable-less designs – soldering or connecting components directly to the circuit board – are cooler, less prone to latency issues associated with the degradation of wiring, and resistant to vibrations.

Finally, utilizing a one-piece chassis for the outer enclosure further protects devices against high-vibration environments. This also has the added effect of further dissipating heat generated by the computer, and creating a more secure sealing that protects internal components from moisture and particulates.

Ingress Protection

Dirt, dust, and other particulates can damage internal components and degrade the functionality of a rugged industrial computer. Moisture can corrode internal components and cause sparking. While moisture and particulates are quite different and produce different negative results for computers, the strategies and approaches to protecting internal components are similar. Again, these solutions aid in both vibration resistance and thermal management as well:

- Fanless, passive cooling designs eliminate the need for vents or holes to expel hot air.

- Utilizing a one-piece chassis for the outer enclosure provides an effective seal against dust and moisture.

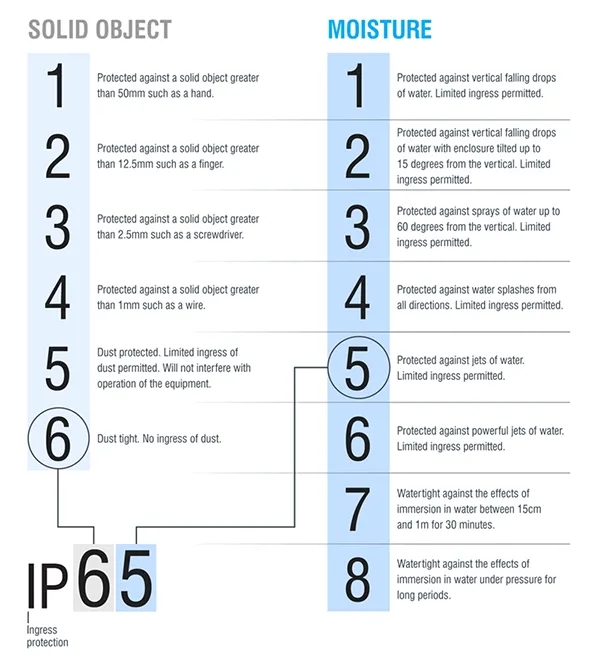

Rugged embedded computers are often labeled with an IP rating. An IP rating is known as the Ingress or International Protection Code and contains two digits. The first digit specifies the degree of protection against solids. A rating of 1 means protection against objects greater than 50mm. Increasing digits indicate protection against infiltration of smaller and smaller objects, ending in a rating of 6 which is dust-tight. The second digit in an IP rating specifies liquid protection. A rating of 1 means protection from water droplets. Higher digits signify protection against increasing exposure to water, ending in a rating of 8 which means protection during full immersion for long periods. An IP65 rating, for example, means the device is dust-tight and will continue functioning with limited ingress from jets of water.

Power Tolerance

Rugged industrial computers must also include fail-safes against power disturbances such as unexpected power outages, voltage spikes, and wide voltage ranges. These disturbances can have negative effects on hardware, causing data loss or corruption. Typically, the types of applications that require rugged computers are in remote or hard-to-reach locations, making it difficult to service or repair devices in the field. Further, the remote nature of the typical deployment generally means that these locations are more prone to things like power fluctuations or blackouts. Therefore, having a battery backup, high-energy capacitors, or other alternative power solutions in place is crucial for rugged industrial computers.

Sealevel Rugged Industrial Computers

Utilizing the design concepts outlined above, Sealevel produced a custom rugged embedded computer that evolve into the Relio R1 Industrial Computer standard product. The original specifications required the ability to withstand operating temperatures of -40°C to 70°C and to operate under shock and vibration levels that are nearly double those required to meet the MIL-STD-810 specification. According to the customer, “the Relio R1 was the only unit tested that passed all tests without any failures.”

Categories: